May 10, 2016 at 10:04 AM

Protect and Enhance Your Print Marketing with Varnish Coating

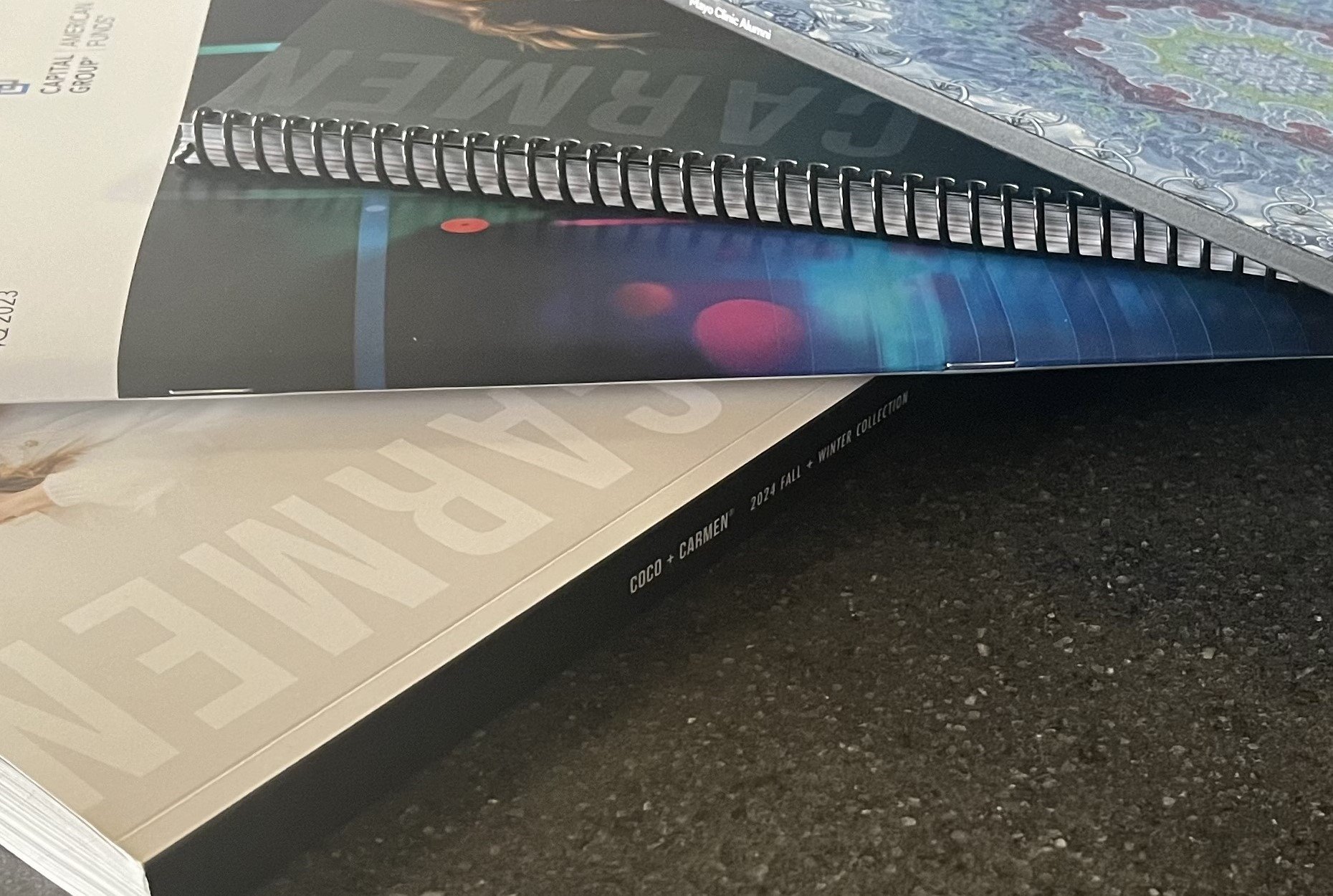

Varnishes and coatings offer a multitude of ways to add impact, durability, and pizzazz to printed materials. Varnishes are routinely used to protect a printed piece from fingerprints, smudges and wear and tear. But they also lend sophisticated nuance when applied selectively, as a design element.

Varnishes and coatings offer a multitude of ways to add impact, durability, and pizzazz to printed materials. Varnishes are routinely used to protect a printed piece from fingerprints, smudges and wear and tear. But they also lend sophisticated nuance when applied selectively, as a design element.

While varnish is a relatively common print technique – it can provide some seriously uncommon enhancements to a print project.

Print Design Techniques

A varnish is a liquid coating applied on press like an ink that is available in gloss, satin and matte finishes and can also be tinted to provide slight color enhancements.

Varnish can be flooded over the entire sheet or spot applied to highlight specific areas. It can also be both wet-trapped (printed at the same time as the inks) or dry-trapped (printed as a second pass after the inks have dried). The dry-trap process offers maximum contrast and tends to be the most visually distinct technique but at a higher cost because of multiple passes through the press.

Applied as a design element, varnish provides contrast that can highlight and enhance a photograph, create subtle images and textures, or set a piece apart with distinctive color application. When printed on a four- or six-color press, one or more of the ink fountains can be used for varnishes, which expand design possibilities and have little effect on cost.

Strikethrough is a popular print technique that adds a dramatic dull/gloss contrast to your printed project by taking advantage of a chemical reaction between a spot dull varnish area and an overall gloss flooded coating. This technique can also be used to create a reticulating (textured) appearance for the spot varnish area.

Print Protection

When matte or dull coated stock is specified, flood varnish or aqueous coating is almost universally recommended. Ink has a tendency to rub off these papers, even when they are carefully handled. A coating that covers the entire piece compensates for the soft nature of the paper, giving it the essential durability of a gloss coated stock. Because gloss, satin, or dull varnishes are available, the look of a piece is not altered by varnish application unless it is an intentional customer decision.

When a piece has solid ink coverage and high hold-out, it is always recommended to be coated, even on a #1 coated sheet. Medium to light ink coverage on the same sheet may not require a varnish coating. High quality printers will formulate inks and varnishes that provide your printed communication with “bullet proof” protection.

Drawbacks of Varnish

While varnish coatings provide a fast and easy way to protect a printed piece, they do have a few drawbacks when compared to other coatings like aqueous and UV.

- Varnish offers the lowest degree of protection of the available print coatings.

- Varnish may yellow over time but this is primarily only noticeable over white non-printed areas of a print.

- Printers may needs to apply offset powder to keep sheets from sticking together, which if done poorly, can affect the look and feel of your printed piece.

As always, it is important to consult with a print sales rep early in the design process when varnish or any coating is part of a design concept. The effects of varnish are difficult to represent on preliminary proofs, and offset lithography does have some physical limitations. Consulting with an experienced printing professional can eliminate misconceptions about the nature of various varnishes, smooth production, control costs, and ensure a finished printed product that matches the concept.

Popular Posts

Memorial Weekend

Landing Pages

Learn Why Omnichannel Marketing is Trending

Direct Mail