February 13, 2017 at 8:22 AM

Print Buyers Guide to Climate and Print Quality

Print quality is affected by numerous factors, such as the type of paper used and the viscosity of the inks to name a few. One of the biggest concerns all print buyers should be aware of is the effect of climate on print quality. Temperature and humidity are responsible for a host of problems including picking, misregister, wrinkling, and curling. Quality issues like these may necessitate pulling or reprinting the job, and that means buyers sometimes must choose between compromised print quality and missing a critical deadline. Neither scenario is acceptable, which is why print buyers should only work with commercial printers with climate controlled production facilities.

Picking

Picking is the result of the tacky ink being applied causing particles of the paper surface to separate from the sheet. Sometimes this causes the appearance of blisters, and in severe cases causes whole sections of the paper’s coating to pull away. This usually happens when the paper holds high moisture content in humid conditions. The force of the ink tack, or stickiness, is greater than the surface strength of the paper.

Curling

In offset printing the blanket transfers the fountain solution (a combination of water and ink) to the paper. Paper absorbs moisture from the blanket which makes the side of the sheet being inked wetter. At first the sheet will curl slightly toward the drier side. As the sheet dries it curls back toward the we tter side. When the air is very dry in the pressroom the sheet has a tendency to curl even more to the wetter side. In laser printing the high heat used to fuse the toner to the sheet causes instant moisture loss, often resulting in curling.

tter side. When the air is very dry in the pressroom the sheet has a tendency to curl even more to the wetter side. In laser printing the high heat used to fuse the toner to the sheet causes instant moisture loss, often resulting in curling.

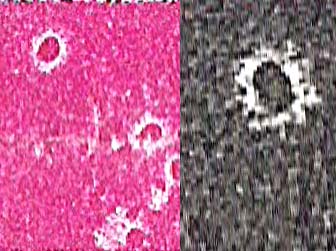

Misregister

Exceptionally dry air during the winter months causes the paper fibers to shrink, especially at the edges of the sheet. This in turn often causes registration issues. When print is out of register the images on the printing plates are not perfectly aligned. The result may be a noticeable line of process color dots at the edge of an image, an undesirable color shift, and images that appear fuzzy or blurred. Paper that has absorbed too much moisture in humid climate conditions sometimes becomes wavy at the edges of the sheet. Wavy paper can also lead to misregister.

Reprinting a job because of poor print quality causes missed deadlines. Missed deadlines are inconvenient at best and catastrophic at worst. Imagine the direct mail portion of a multichannel marketing campaign arriving in homes after a special sale event, or not having the new product line brochure for the annual trade show at which you paid thousands of dollars to exhibit. Many commercial printers know how to minimize the effects of climate on print quality. It pays to trust your printing and mailing projects to a printer with year round climate control of their production facility and the experience needed to avoid print quality issues.

Popular Posts

Memorial Weekend

Landing Pages

Learn Why Omnichannel Marketing is Trending

Direct Mail