June 27, 2018 at 8:50 AM

A Print Buyer's Guide to Binding Techniques

Recently a print buyer from an agency requested a mockup of a side-sewn bound book needed for a presentation. He provided detailed specifications down to the color of thread and the paper stocks required.

When he received the mock-up he realized side-sewn did not match how he pictured the book should look. It turned out what he really needed was a Smyth-sewn book. He had to do the presentation without the correct mock-up.

Like many print professionals, he wasn’t aware of the difference. Whether you are producing a book, brochure, calendar, or pamphlet, it is important to know what options you have for binding together printed pages.

The following guide to binding covers the common mechanical binding techniques utilized today in commercial printing. First though, understanding some of the basic terminology will be helpful and then we'll get into the many ways to bind a book!

Binding Terms

Head – The top of the book, opposite the side the book rests on when shelved upright.

Face – The parallel side opposite the bound edge.

Foot – The bottom of the book when shelved upright.

Spine – The bound edge of a book.

Leaf - A single sheet of paper.

Page - One side of a leaf, front or back.

Folio – A printed sheet folded in half which makes 4 pages in a book. In an 8-page brochure, for example, there are two folios nested together. The first folio is printed with pages 1/2 to the left of the fold, with pages 7/8 on the right side. The second folio nested on top of the first is pages 3/4 & 5/6. The lowest numbered side at the front of the book is called the Low Folio. The highest numbered side at the back of the book is called the High Folio.

Signature – Four or more pages printed on both sides of a press sheet in a layout which, when folded one or more times, creates a group of pages in numerical order and slightly larger than the final trim size. Depending on the size of the press sheet and the finished size of a page, a typical signature is 4, 8, 16, or 32 pages. The page layout on the sheet is called the Imposition or printer’s spread. An 80-page book may be produced from five 16-page signatures, as an example, and usually would be numbered Sig-1 through Sig-5 in correlation to their place in the book and corresponding pocket during gathering on the mechanical binding equipment.

Book Block (also called Text Block) – The stacked signatures or loose single pages which make up the body of the book.

Headband – A decorative piece of fabric glued to the spine at the head and foot for concealment of adhesives and stitching.

Case (also called Hardcover) – The three piece assembly of front cover, spine, and back cover made of binder’s board wrapped in book cloth, known as the “Case” in Case Binding.

Binder’s Board – A type of paperboard used to make the hardcover “case” in Case Binding. Binder’s Board is produced in various thicknesses, commonly between 70pt (.07 inch) and 98pt (.098 inch).

Book Cloth (also called Buckram) – A woven fabric such as burlap that has been coated with various chemical compounds including starch and subjected to heat and pressure to produce a durable cloth with a range of textures and finishes. Book cloth is used in Case Binding hardcover books, and is available in many colors.

End Sheets (also called End Leaves or End Papers) – Sheets of paper folded in half with one half affixed to the inside of the case and the spine of a book block. The other half remains loose. The loose half is called a Flyleaf. The paper stock used is typically a 7pt or 9pt uncoated cover, most often blank, although printing the end sheets is an option.

Binding Type: Stitched

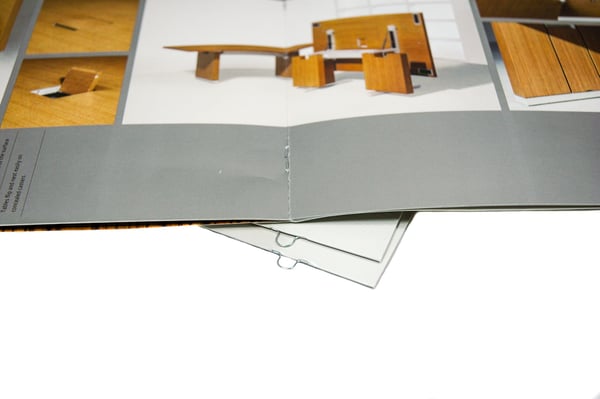

Saddle Stitching (also called Wire Stitch)

The most popular binding method, saddle stitching, is also the easiest and most economical. The printed sheets are trimmed and folded into 4-page folios. The folios are gathered and nested one inside the next, as opposed to simply stacking. Two or three wire staples are driven through the center of the folded spine.

A three-knife trimmer then trims the three non-bound edges to the specified final size to create the book.

When folios are nested one inside the next, the thickness of the book creates creep where the inner folios stick out past the face of the outside folios. Trimming the face makes the edge uniform, but creep must be accommodated for in the pre-press stage of the project in order to make all of the margins throughout the book uniform.

Loop Stitching

Loop stitching is a variation of saddle stitching where the staple wire extends beyond the spine to form a loop so that the bound product can then be placed into a three-ring binder or later threaded together. Loop stitching is primarily used for manuals, notebooks and reference materials that will ultimately end up in a binder.

Binding Type: Glued

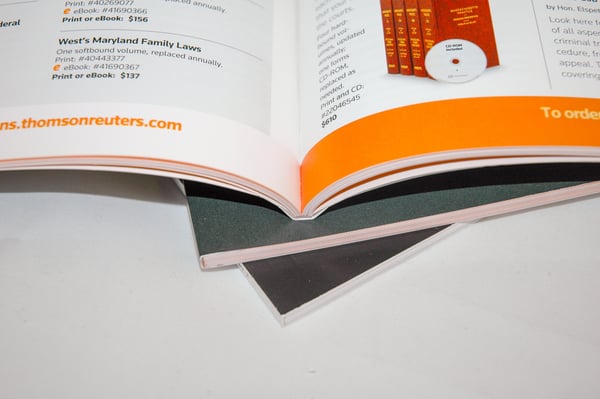

Perfect Binding (also called Adhesive Binding)

Perfect Binding is used for softcover books. The cover is printed separately from the inside pages and on a heavier, stiffer paper stock. The inside pages are printed in folded signatures. The signatures are loaded into pockets along the length of the perfect binding machine and mechanically gathered. Once gathered the signatures are held in a clamp and the spine is milled with a rotary grinder to remove the folds and provide a rough surface for optimum adhesion. Next the book block has a hot-melt adhesive applied with rollers that force the glue into the spine. The cover feeder scores the cover to allow it to fold at the edges of the spine without cracking. Optional hinge scores may be added 3/16” to 1/4” from the spine for a higher quality appearance. The cover is then pressed against the spine, folded around the book block, and clamped. The book is released onto a long conveyor belt which travels upward in a series of spirals, allowing the glue to cool and dry. Finally the book is fed into a three knife trimmer which trims the book on the head, foot, and face to the desired finished size.

Modern perfect binding machines use a polyurethane reactive adhesive known as PUR glue. PUR is a hot-melt, clear glue. PUR is the most popular adhesive because it is durable, dries to 80% of full bond strength in a few hours, remains flexible when dry, bonds well to both coated and uncoated paper stocks, and allows books to lie flatter when open. Older perfect binding equipment use Ethylene Vinyl Acetate (EVA) which is also a hot melt application. Unlike PUR, EVA is white and much thicker, making it more noticeable when dry. EVA also yellows and has a tendency to chip and crack over time.

Minimum finished size: 3” x 4” x 1/8”

Maximum finished size: 12” x 16” x 1-1/2”

Allow a minimum of 1/8” for trims and spine grind. Paper stock should have grain running parallel with the spine.

Lay Flat Bind (also called Otabind)

Lay Flat binding is a variation of perfect binding which allows a book to open fully and remain flat when laid on a table. This is achieved by gluing a cap to the book block, then gluing the cover only to the first and last pages of the book block, leaving the cover unattached to the spine. Otabind is a licensed lay flat binding system. Many graphic arts professionals still call lay flat by the Otabind label, much like some people continue to refer to a photocopy as a Xerox.

Binding Type: Sewn

Side Sewn (also called Over-sewing)

Side-sewn binding is a good option for books too thick to bind using other methods, up to around five inches thick. In side-sewn binding the signatures or loose sheets are gathered and clamped, and small holes are drilled through the book block from front to back along the left margin. A heavy gauge needle with binding thread is used to stitch the signatures together.

Side-sewn book blocks can be cased-in with a hardcover, or have a softcover affixed to the spine with adhesive, but often are produced with the cover over-sewn as shown in the photo. Many colors of binding thread are available.

A drawback to side-sewn binding is the book will not lie completely flat when opened, and copy close to the spine is difficult to read.

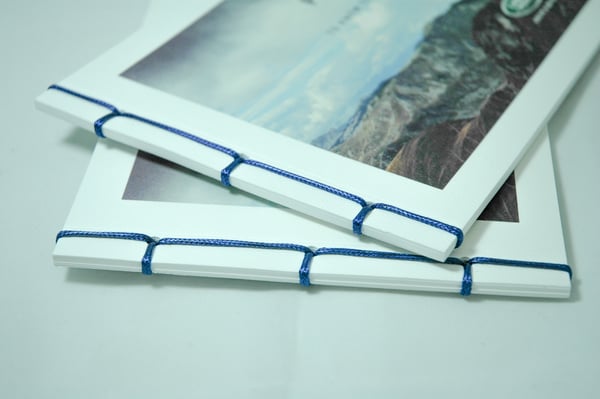

Smyth-Sewn (also called Section-sewn)

Smyth-sewn books are the most durable and the highest quality in commercial binding, plus have the added benefit of being able to lie completely flat when opened. Textbooks, archival books, log books, notebooks, and library books are good examples.

The signatures are stitched together in groups through the folds using a heavy gauge needle, binding thread and multiple stitches. Then the groups of stitched signatures are stitched together to form a book block. The threads get tied off and a piece of sturdy fabric such as burlap is glued to the spine for added reinforcement.

Often a decorative headband is also added at the head and foot of the spine between the text block and the material covering the spine. A Smyth-sewn book block can be cased-in or have a softcover affixed with adhesive.

Binding Type: Case

Case Binding

Case binding is used for hardcover books, and can be done with a sewn spine or adhesive only. Sewing the spine offers the greatest strength and durability. (See Smyth- Sewn) The cover or “case” is composed of binder’s board wrapped with book cloth, or wrapped with printed sheets that have been laminated for added strength. The folded signatures are collated and stitched or glued together on the spine to form a book block. The book block is trimmed on the head, foot, and face to the finished size.

A headband is sometimes affixed to the spine as a decorative touch and to strengthen the spine. End sheets are glued to the book block on the spine and to the inside of the case. Whether or not the end sheets are printed is an additional design consideration. There is no need for a dust jacket if your cover was produced with printed, laminated sheets. Because case binding is complex I recommend asking your printer or book binder for a template at the start of your project’s design phase.

Binding Type: Coils

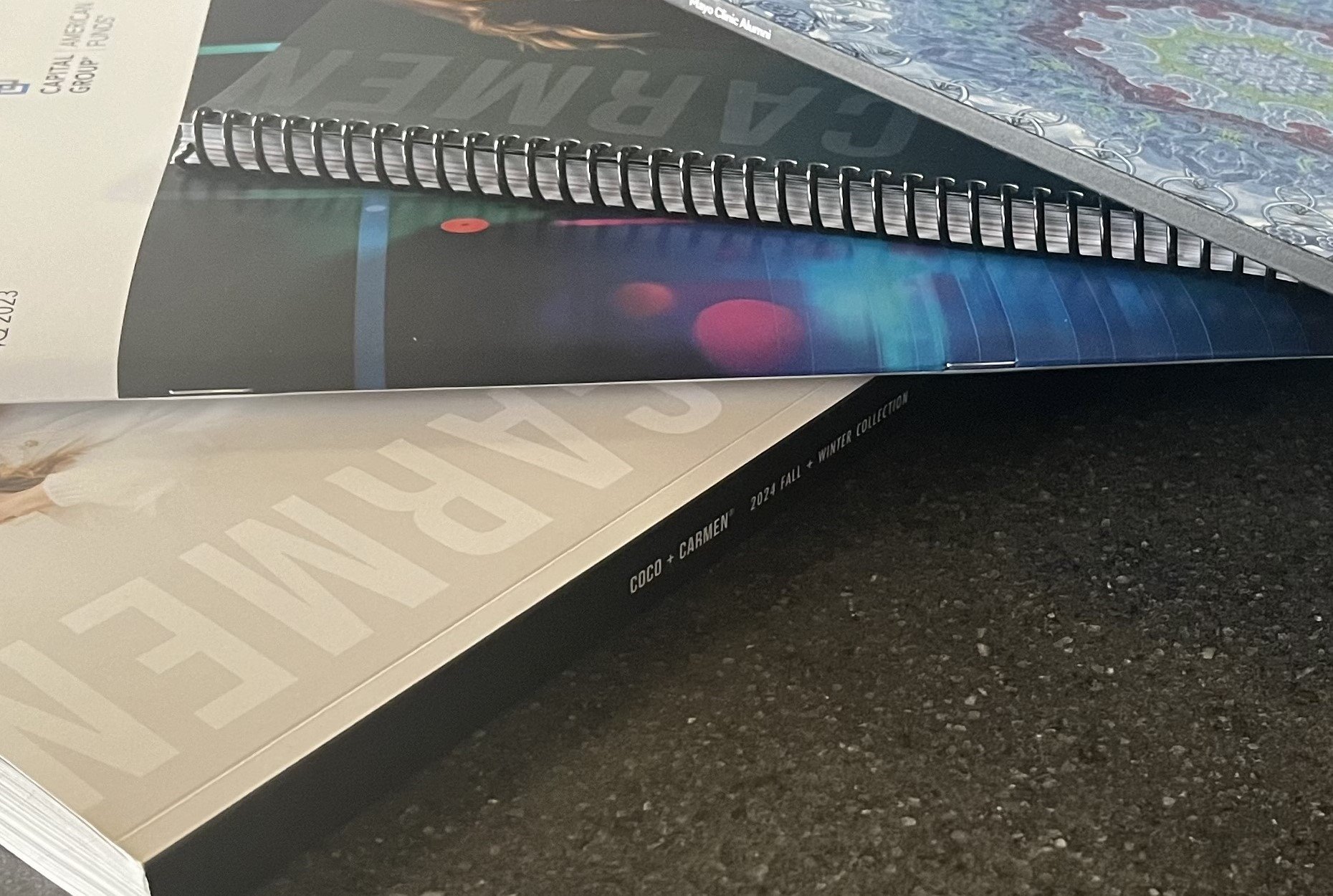

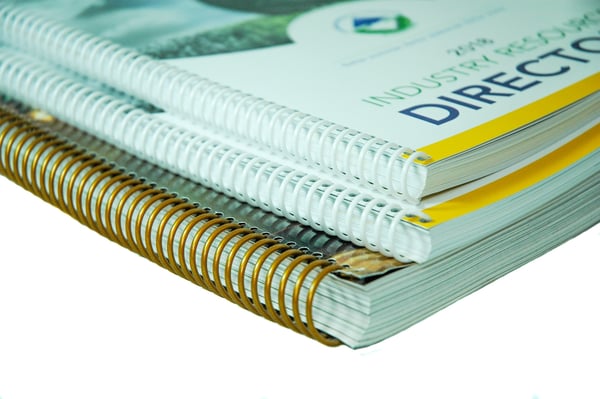

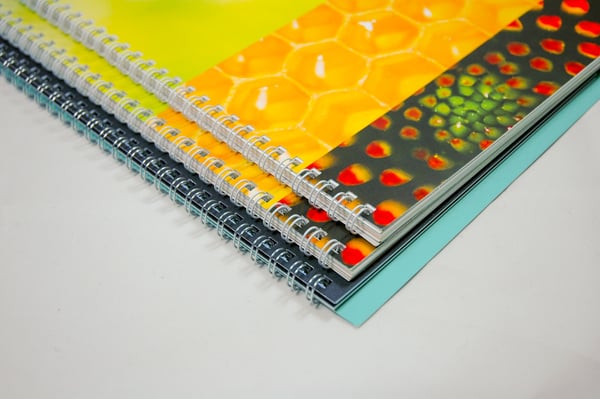

Spiral Bind (also called Coil-bind and Plastic Coil)

Spiral Binding is used when a book must be able to open 360 degrees. Cookbooks, manuals, instruction guides, reports and directories are good examples of common use. The folded signatures or loose sheets are gathered to form a book block. In the case of signatures, trimming is performed on all four sides to the desired finished size.

Loose sheets are most often printed digitally and output as a collated book block. Loose sheets may also be press printed, trimmed to finished size, and mechanically gathered to form a book block. Typically a separate front cover and back cover are added to the book block. Sometimes a clear acetate sheet is also added on the front and back for added protection. Index tabs are a common feature. Holes are punched along the left margin in a pattern dependent on the size of the plastic coil.

The most common punch patterns are 3:1 pitch (3 holes per inch), 4:1 pitch, and 5:1 pitch. Once the holes have been punched a flexible plastic coil, which looks like a long spiral or spring, is fed through the holes. Plastic coils are available in many different colors. Plastic spiral binding can accommodate books up to 2” thick with up to a 20” binding edge.

Comb Binding

Comb Binding uses a plastic spine with curved prongs called a comb to bind the sheets. The book block is punched with rectangular holes spaced 9/16” apart along the margin to be bound. On an 11” spine there are 19 holes. This is called a 9/16” punch pattern. The comb is fed through the holes to join the pages. It is a good option if you only need a small quantity bound.

With the right equipment you can easily do your own comb binding. Desktop comb binding machines and supplies are relatively inexpensive. Plastic combs are readily available in many colors and sizes. One of the big benefits to comb binding is the book can be taken apart easily and the combs reused.

Wire-O Bind (also called Twin Loop and Wire Loop)

Wire-O binding is used frequently for reports, instruction manuals, and guides books. The metal finish provides a more upscale, professional, appearance. Like in Spiral Binding the book blocks are punched with holes spaced along the left margin.

The most common punch patterns are 2:1 pitch (2 holes per inch) and 3:1 pitch. The wire used is in a strip with C-shaped twin loops spaced 2 or 3 pairs per inch. The wire loops insert into the punched holes and get mechanically pinched closed to secure the pages. The wire is available in multiple sizes and colors. Wire-O binding can accommodate books up to 1” thick with up to a 20” binding edge.

Summary

There are obviously quite a few binding options available and this list isn't all-encompassing. Choosing a binding method can be a difficult choice to make - we recommend thinking about how the end-user will be interacting with your product to help guide your decision. We also highly recommend consulting with a printer ahead of time to make sure your project ultimately comes together successfully!

The technical specifications for any of the binding methods covered in this guide vary depending upon the equipment being used. Not all printers and binders own the same equipment. Again, ask your printer for templates to aid in the design and preparation of graphic art files. They will be happy to offer assistance, including making suggestions for binding based on the number of pages, purpose, end user considerations, and budget.

Popular Posts

Memorial Weekend

Landing Pages

Learn Why Omnichannel Marketing is Trending

Direct Mail