April 1, 2016 at 10:00 AM

3 Web Offset Printing Myths Demystified

Years ago, printing on either a web press or sheetfed press was a clear-cut choice – your project was a fit for one or the other. With today’s technology and state-of-the-art equipment, such distinction between web and sheetfed printing has been erased. Now you can glean the efficiencies and advantages of both processes – often on the same project – while enjoying optimum results.

A big reason for that is the improved paper selection available for today’s web printing presses. Following are some common “myths” about web and sheetfed printing that we’d like to clear up:

Myth #1: Web printing has quantity restrictions

The dividing line between sheetfed and web is no longer 20,000 impressions. In fact, depending on your project’s specifications, you may find significant cost savings by printing 15,000 impressions or less on a full- or half-web press. It's important to spend some time up-front with your printer to determine the best press platform for your project.

Myth #2: Web printing has paper limitations

Web paper quality has vastly improved, blurring the distinction between what is produced in rolls versus sheets. Many premium-grade stocks are now available for web presses, letting you take advantage of both press formats without compromising in stock selection. Web paper is specially designed to ensure quality is maintained on press and in the bindery – e.g., the moisture content is 7%-10% higher to withstand drying needed for high-speed runs, and the paper’s grain runs along the length of the press for better folding results.

Myth #3: It's all or nothing

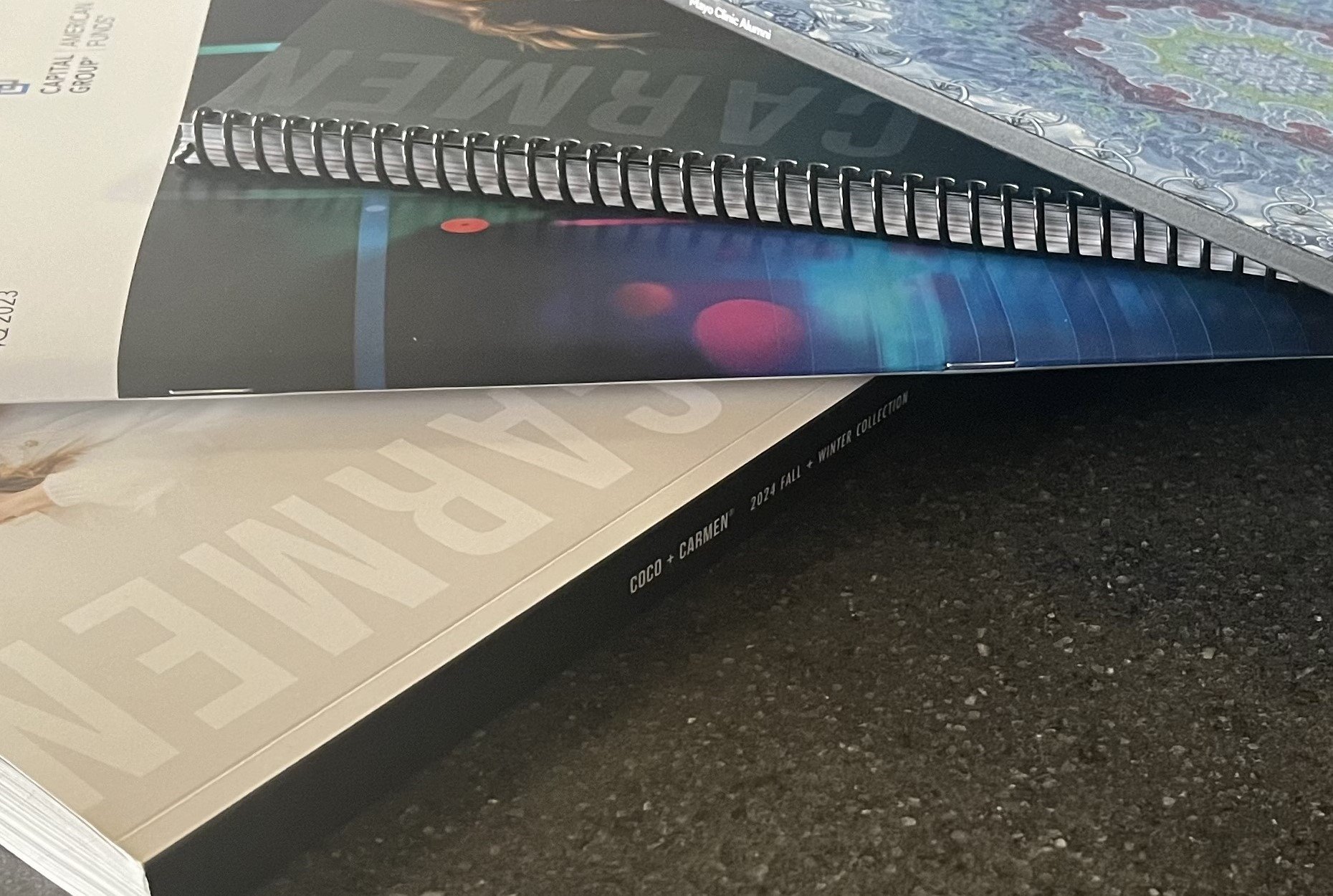

In many cases, both web and sheetfed presses can be used to produce one project. The best printers house both types of presses under one roof, giving you greater flexibility in finding high-quality yet cost-effective solutions. For example, catalog covers requiring spot colors, UV coatings or other premium processes can be printed on a sheetfed press, while a half-web press or full-web press can be employed for printing the inside pages.

For top-notch printers, craftsmanship and state-of-the-art equipment allow you to enjoy the type of high-quality results you would expect from a sheetfed process while gaining the economies of the web. Discuss your printing needs with your print sales rep in the early stages of your project design to determine the best production process for your needs.

Popular Posts

Memorial Weekend

Landing Pages

Learn Why Omnichannel Marketing is Trending

Direct Mail