February 2, 2017 at 11:17 AM

The Web Creep Phenomenon

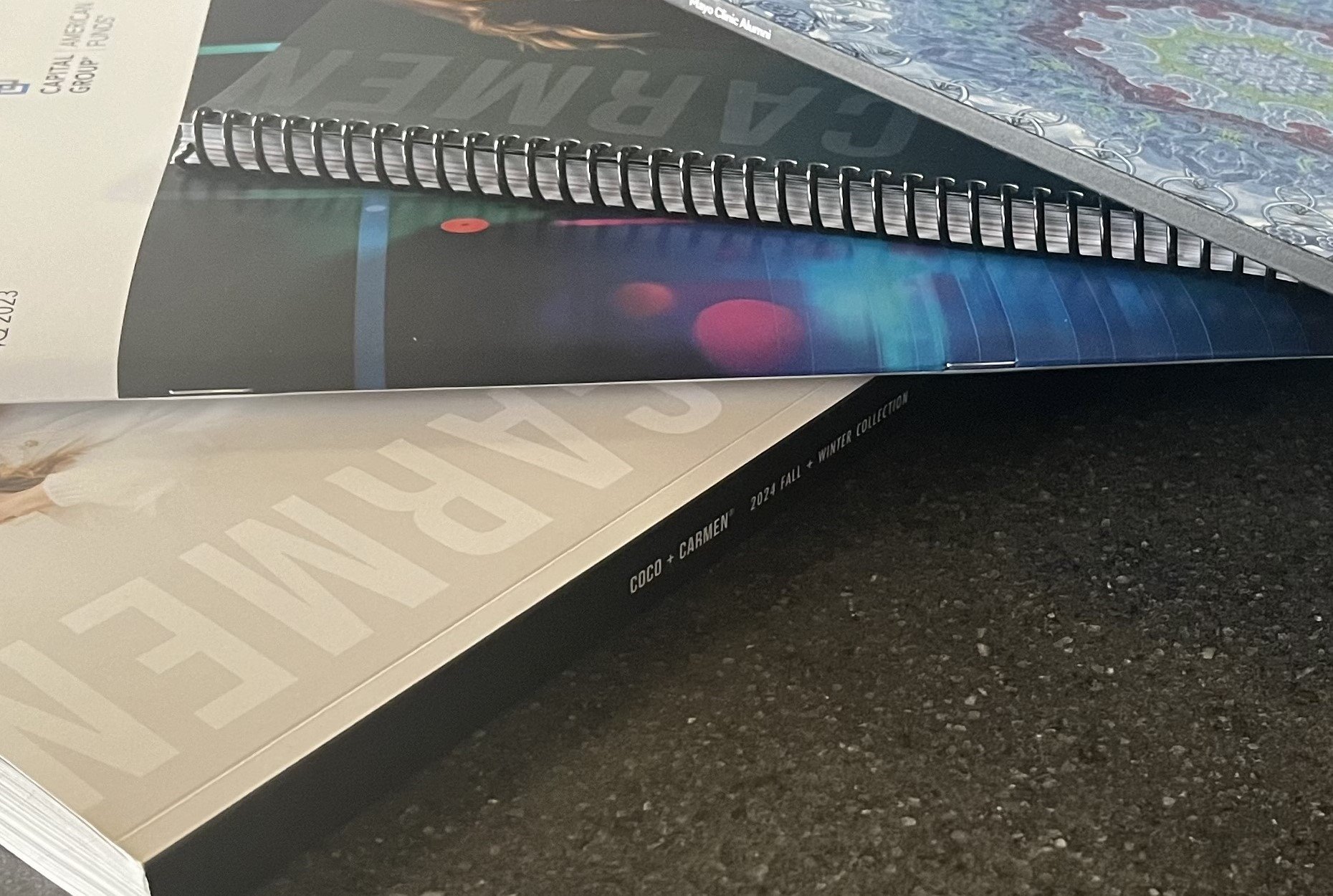

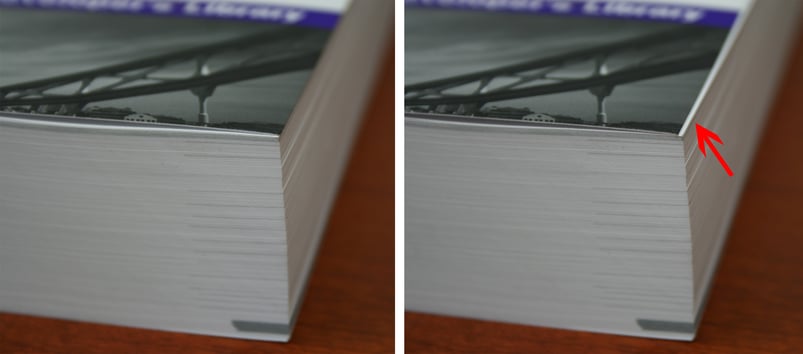

Have you ever seen a catalog with the inside pages protruding further than the cover? In appearance the cover looks slightly too small. You might assume the printer trimmed the cover incorrectly or perhaps there was an error during perfect binding. What you see was not a mistake or intentional. It is called Web Creep or Web Growth and is a common problem when catalog covers are printed sheetfed and inside pages are run on a heatset web press. The effect of Relative Humidity (RH) on paper fiber, the use of dryers in web offset printing, and insufficient time for conditioning are the main causes. Controlling environmental conditions of paper storage and pressroom are important for preventing web creep and other undesirable effects caused by unstable temperature and humidity.

Paper is subjected to different temperatures and levels of RH at the paper mill, during transport, in storage at the paper supplier, in storage at the printer, in the pressroom and bindery. Relative Humidity (RH) is the amount of water vapor content in the air in relation to how much moisture the air can hold at that temperature. When RH is high the paper fibers in the sheet or roll will absorb moisture and expand. When low, the fibers shrink. For optimum print quality it is critical that the paper achieves RH equilibrium, a balance between the temperature and moisture content of the paper with that of the surrounding air. Allowing time for paper to achieve RH equilibrium is called conditioning.

Web Creep happens when the catalog or book cover is printed on a sheetfed press and the inside pages are printed on a heatset web press. The inside pages (signatures) are subjected to high temperatures in the heatset dryer unit which causes the paper to lose moisture content and shrink. If these dry signatures are bound with the covers before the paper has time to condition and achieve RH equilibrium, the inside pages will absorb moisture and expand after binding. The end result is a finished book or catalog with web creep.

During winter months in much of North America the air is cooler and dryer. Desert regions also have dryer air. This is also true of higher altitudes where the lower oxygen level causes the air to hold less moisture. Summer months see increases in humidity. Many commercial printers, including The John Roberts Company carefully maintain a climate controlled plant. This includes whole facility humidification from late autumn through early spring, and air conditioning during warmer months.

According to Printing Industries of America a properly climate-controlled facility includes humidification that maintains approximately 45% RH @ 72° for North America.

A few other steps can be taken to prevent web creep. Printers should leave sheet and roll stock wrapped until going to press. Order paper early so it has time to reach RH equilibrium, and build time into the production schedule to allow the web printed signatures ample time to condition prior to binding.

For a thorough explanation of the effects of temperature and humidity on paper and printing visit Printing.org.

Popular Posts

Memorial Weekend

Landing Pages

Learn Why Omnichannel Marketing is Trending

Direct Mail