August 17, 2017 at 1:06 PM

Commercial Printers Reduce Print Costs and Maximize On-time Delivery

Behind the emerald curtain in the Commercial Printing industry a war quietly rages. Rather than a war between good and evil, this war is fought between Account Executives, and Production is trapped in the middle of the fray. Account Executives seeking new business in a fiercely competitive marketplace often agree to tight turn times or seemingly impossible deadlines. Production is charged with completing all projects for every client accurately and on time. The number of projects and client expectations frequently create production scheduling conflicts, bottlenecks in the availability of equipment and labor. In the past, many printers resolved scheduling conflicts based on factors such as an existing client’s annual revenue or new client’s potential future revenue. But this is a new era and technology is rapidly evening the playing field through the implementation of sophisticated plant management software and scheduling automation.

During my career in Printing and Direct Mail I have worked in both Sales and Production. As an Account Executive I routinely saw my client’s projects get bumped on the schedule. It didn’t matter if my project was for a new client that I had been pursuing for more than a year. It didn’t matter if my new client had great potential for more business. When push came to shove dollar signs always determined the outcome. Telling a client that their project is not going to ship or mail on time is embarrassing and can be a horribly unpleasant experience. I quickly learned that I needed to pad my project schedules by at least a few days, and I needed to get every department manager on board with my client’s project timeline. I strongly encouraged clients to stick to an agreed upon schedule, supply correct art files from the start, review and approve proofs quickly, and supply lists in advance. I had to be at the top of my game when it came to managing my client’s expectations. The stress was palpable.

From a Production viewpoint, every schedule on every project is constantly in flux with numerous factors affecting the workflow. The following is only a partial list.

Has art been received?

Do any images require color correction?

Is variable print required and has the data file been furnished?

Have proofs been approved or will alterations be required?

Are there any non-print materials required which need to be purchased?

Is the paper stock on the floor, in transit from a supplier, or weeks out because a paper mill must manufacture more?

Does the final product require special dies, die-cutting, foiling, or embossing?

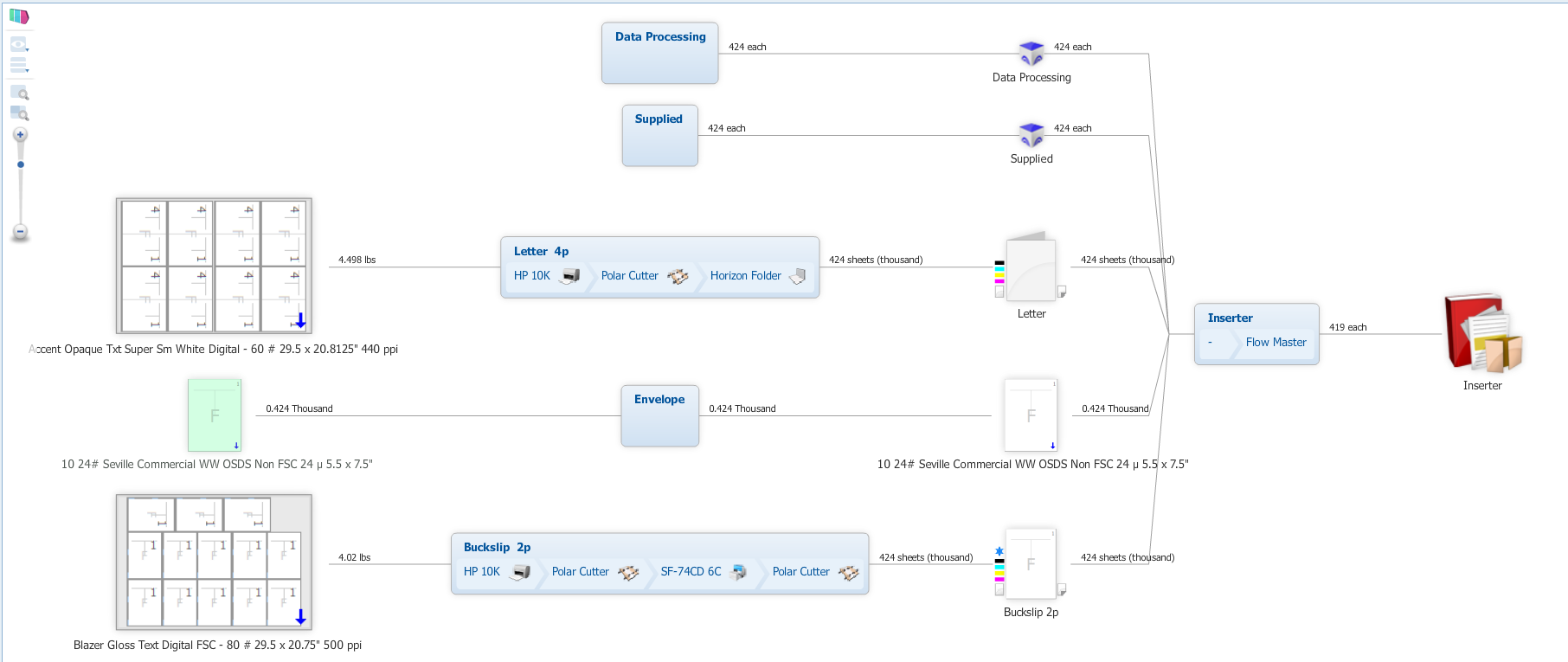

John Roberts recently upgraded what was already a very sophisticated project management system. The new, state of the art software seamlessly unites estimating, project entry, scheduling, and resource management. Every machine in the plant is wired into the system, showing in real time which equipment is paused, being set up, or running. Run rates, start time, end time, paper and ink usage, and many other factors are automatically calculated. The program adjusts the schedule for every piece of equipment in the plant every time an estimated project becomes a live job.

The job of the scheduling manager is still incredibly challenging. There will always be unexpected hiccups which cannot be accounted for in a production schedule. Machines break. Parts sometimes need to be flown in from other states or other countries. A blade that was razor sharp yesterday is suddenly too dull to cut cleanly. Paper arrives from a supplier in the wrong sheet or roll size. But now the scheduling manager has a powerful tool with which to effectively manage the schedule, allowing manual adjustment of individual processes. Each manual change produces an automatic update for every piece of equipment. Those bottlenecks in availability of resources which formerly would have caused conflict and potential disappointment are now minor bumps in the road. The end result is a maximization of on-time delivery.

The war is all but over. Technological advances in software development are revolutionizing the commercial printing industry. Estimates are more accurate, turn times are more manageable, and machine utilization is maximized. More projects are produced on time and on budget than ever before. The giant job boards of the past are being replaced by monitors and algorithms. The biggest winners are the customers. More accurate estimating and more efficient production result in better pricing, higher quality, and critical due dates met without fanfare.

Popular Posts

Memorial Weekend

Landing Pages

Learn Why Omnichannel Marketing is Trending

Direct Mail