May 26, 2016 at 8:30 AM

Print Buyers Guide: How to Choose the Right Paper for Your Project

If you’re overwhelmed when choosing paper for your next job, you’re not alone. Paper options abound. Project uses vary. Mistakes are expensive.

If you’re overwhelmed when choosing paper for your next job, you’re not alone. Paper options abound. Project uses vary. Mistakes are expensive.

In our experience, a few rules of thumb can simplify things. As you move your project from concept to print production, the time you take to review its purpose influences the success of your decisions. These basic questions can help state your objective, then help you analyze your options and costs.

Ask yourself:

- What am I working to accomplish?

- What does the audience for this piece expect?

- How long should the final product last?

- Will it be used heavily, or tossed after a couple of days?

- What’s the final size?

- Are there photographs?

- Does the printed piece contain any folds?

- Are there pages with heavy ink coverage?

Basic questions but important because they help you avoid the snag of putting budget before production capabilities. The goal is a piece that succeeds. And while it’s possible you’ll pay a little more after making your assessment, that’s preferable to the waste and disappointment of a project that doesn’t work. None of us wants a brochure that poorly shows expensive photography, letterhead that won’t print in the laser printer, or table tents that slump when they should stand up.

Familiarize yourself with the properties of paper and communicate well and often with your printer. Your printer should have extensive knowledge of paper options and will always be able to provide paper samples and even printed mockups for you to check out before you make a final decision!

Gloss

Gloss is reflection of light. Cast coated papers, smoothed against polished drums as they dry, reflect light because they have little surface texture. Glossier supercalendered papers are taken a step further, polished for high gloss and better ink holdout.

Brightness

Brightness is a measure of reflection of diffused light, and is classified by levels. Number 1 grade paper has a minimum brightness rating of 85, while a Number 2 grade has a minimum of 83, and Number 3 of 79. The brighter the paper, the brighter the white space and the colors.

Opacity

Opacity is resistance to the transmission of light, or show-through.

Weight

Weight of the sheet determines the body of the finished product. If a project needs to stand up, heavier weight is important. Weight influences both the feel and the durability of a printed piece. It is often important when there are multiple folds or die-cuts.

Grain

Grain is an important consideration when a piece will be folded. Folds should work with the grain so they are smooth, with no cracking.

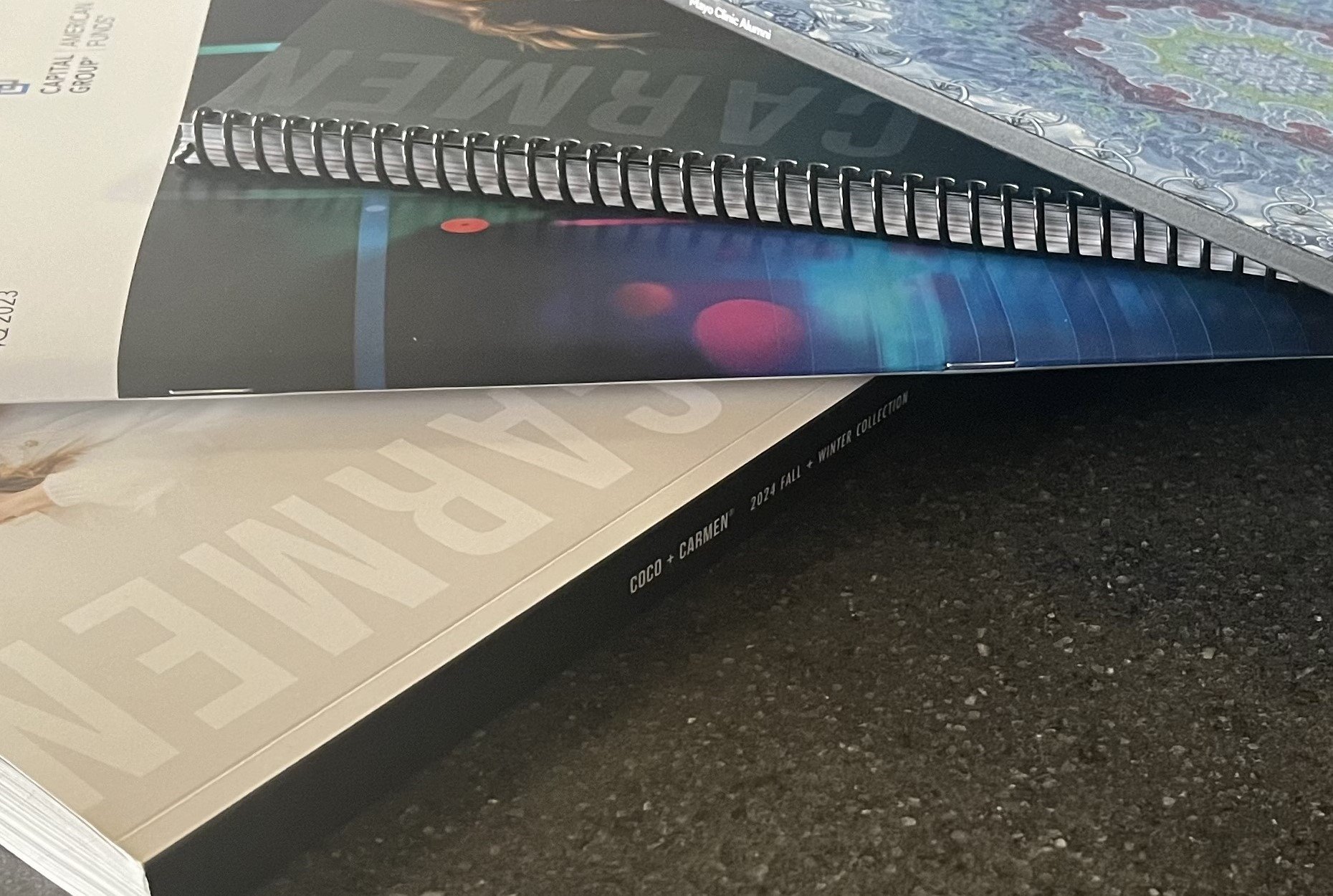

Caliper

Caliper measures the thickness of a sheet of paper. It can be an important consideration for mailing, or bookbinding.

Ink receptivity

Ink receptivity is determined by the smoothness of a sheet. Uncoated stocks, rougher on the surface than cast coated papers, have high ink receptivity because they’re more absorbent. The polished surface of supercalendered papers has low ink receptivity, and offers better dot reproduction.

Tensile

Tensile and tear strength are important when a piece will be die-cut, perforated, glued or folded.

Ultimately, you want a paper that looks great and has production capabilities that will make your project an unqualified success. The good news is, there’s usually a paper that works and fits your budget. Your task is to be clear about requirements.

Popular Posts